Water Treatment Plant #1

Water Treatment Plant #1 has been serving Palm Coast since 1977 and is located on Palm Coast Parkway. It uses groundwater from local aquifer wells and has the capacity to treat up to 6 million gallons of drinking water per day, helping supply a large portion of the city.

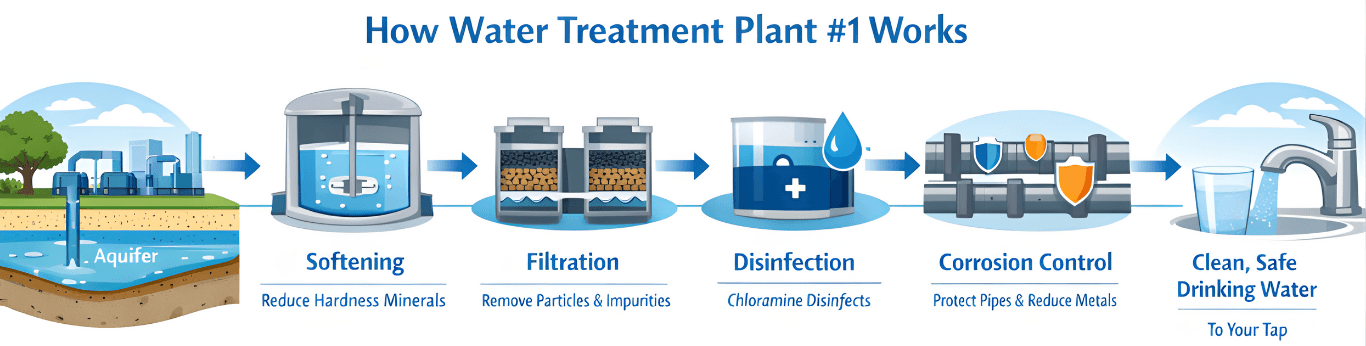

How Water Is Treated at This Plant

At Water Treatment Plant #1, water goes through several steps to make it safe and reliable for everyday use:

- Softening: Minerals that cause hard water are reduced to improve water quality.

- Filtration: Water is filtered to remove small particles and impurities.

- Disinfection: A disinfectant called chloramine is added to kill bacteria and viruses, keeping the water safe as it travels through pipes.

- Corrosion control: Treatments help protect plumbing and reduce the chance of metals like lead or copper leaching into water.

Safety and Testing

The treatment process at this plant meets all state and national primary drinking water regulations. Testing confirms that harmful microorganisms are effectively removed, and the water delivered to customers is safe to drink.

Questions? We've Got Answers!

Find quick answers to common questions about Palm Coast’s drinking water, including appearance, taste, safety, billing-related water use, and what to do when something seems unusual.