Water Treatment Plant #3

Water Treatment Plant #3 serves the northern area of Palm Coast and has been in operation since 2008. It was built to support growth in this part of the city and can treat up to 3 million gallons of drinking water per day using advanced treatment technology.

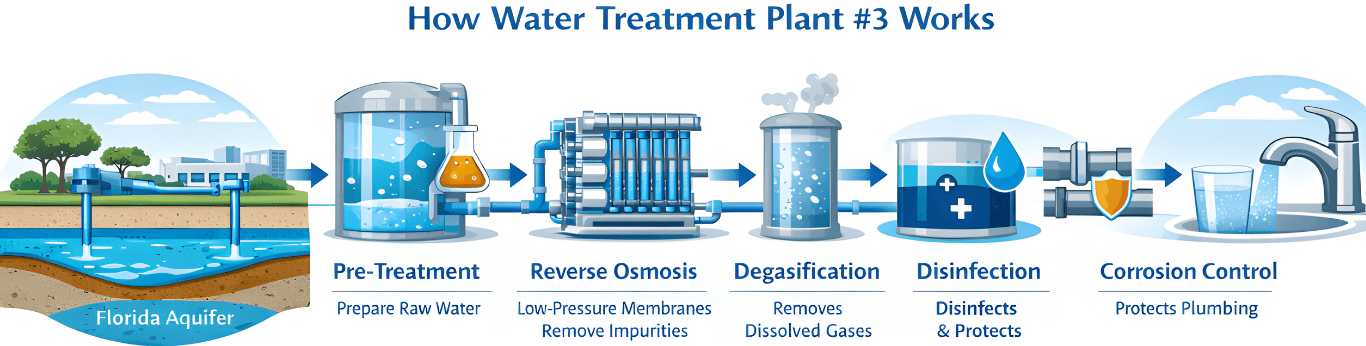

How Water Is Treated at This Plant

Water Treatment Plant #3 uses a multi-step process designed to produce high-quality drinking water from local groundwater sources:

- Pre-treatment: Raw water is prepared for filtration.

- Reverse osmosis: Low-pressure membranes remove minerals and impurities.

- Degasification: Dissolved gases are removed to improve water quality and reduce odors.

- Disinfection: Disinfectants are added to eliminate bacteria and viruses and keep water safe as it travels through pipes.

- Corrosion control: Final treatment helps protect plumbing and reduce the risk of metals entering the water.

Safety and Testing

The treatment process at Water Treatment Plant #3 meets all state and national drinking water regulations. Regular testing confirms that harmful microorganisms are removed and that the water delivered to homes and businesses is safe to drink.

Questions? We've Got Answers!

Find quick answers to common questions about Palm Coast’s drinking water, including appearance, taste, safety, billing-related water use, and what to do when something seems unusual.